Industrial Vacuum Cooling has been introduced to the market some years ago, primarily by the Dutch Verhoeven Bakery Family (BVT / NewCap / Vacuum Cooling & Baking Company). In the meantime this game-changing application has been appreciated on a Worldwide scale.

The continuous -fully automated- system to cool baked products such as bread, toast, croissants, muffins, buns and rolls is part of the extensive product range the group of companies can offer Industrial bakeries.

The development of processes like Vacuum Cooling opens up a whole new perspective for the market of food production. Although technically incorrect, the term ‘vacuum baking’ is often used in the bakery industry, implying the fact that the Vacuum process has great influence on the baking process. While the baking process can significantly be shortened, a different baking profile and baking curve arises.

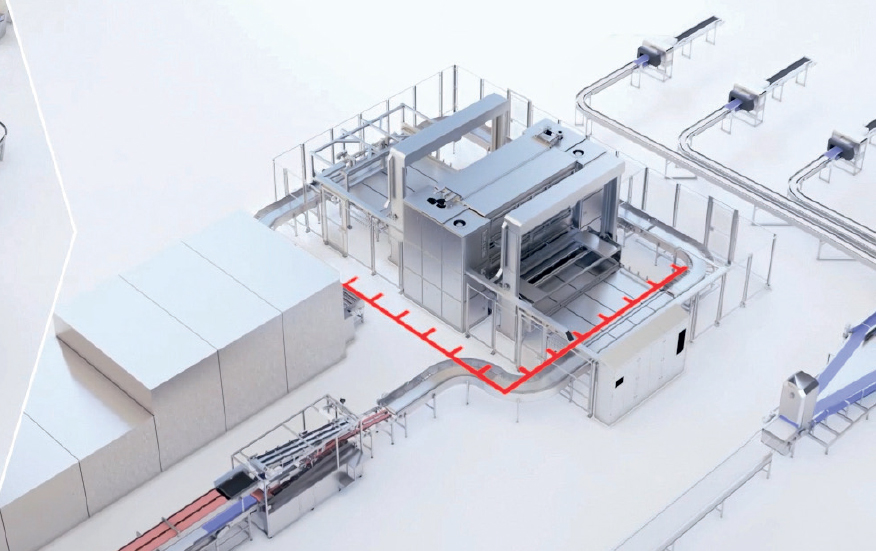

Picture 1: A vacuum cooling system is shown. This 25 m2 system could replace a traditional 250 m2 spiral cooler. Nevertheless the size of the vacuum cooling system is product dependent.

The first continuous Vacuum Cooling systems have been installed at major Industrial bakeries over the world. By integration of this technique in the bakery production environment the average production capacity could be raised by 30-50%, because of the substantial reduction of the production time. Industrial Vacuum Cooling has now been applied for the production of standard baked products such as toast, biscuits and apple pies, but also for special products such as Gluten free. The implementation has resulted in substantial cost reduction and quality improvements.

Most of these customers are continuously looking for a better quality of their product. But the investment is based on more than quality improvement alone. The scale of economics can be obtained by saving on space (the system is substantially smaller than a conventional cooling system) and on ingredients (the volume of the product is increased by Vacuum Cooling). Furthermore the reduction of the ecological footprint is supported by a massive decrease of the huge energy consumption which is an important characteristic and one of the future challenges for the bakery industry.

The continuous Vacuum Cooling Process is much less time consuming than the conventional one. The modular designed installation is compact. The cells are stackable and can swiftly be loaded and unloaded. The ingenious operating system allows a rapid, partly pulsing increase and a controlled decrease of the vacuum. The Vacuum Cooling process enables a high capacity of production. The room capacity is customised and modified to the conventional oven production requirements. The system can be scaled up to quantities of 45.000 cakes, 54.000 croissants or 12.000 toast breads per hour, depending on the capacity of the preceding production line, the recipes and baking processes.

The average cooling time for the products is reduced to 2-3 minutes instead of 60-90 minutes. At the production of Zwieback Toast, the maturing time of up to 24 hours can even completely be abolished.

Next to the production of batch chambers for bakery products the Dutch company offers tailor made Vacuum Cooling solutions for the production of other product like sauces, soups and fillings, tailored to the recipes and production requirements. The systems are wanted because they are suitable for versatile applications which allows the use for a variety of products.

The operating system forms the heart of the process and system. The product quality can be maximised and an increase of the volume can be realised due to a substantial reduction of the baking time. While the product is still dynamic the product quality is influenced and the capacity of the oven can be increased with 25-40%.

The Vacuum cells are closed and therefor the heat loss which occurs in the conventional cooling process, can be efficiently regained through heat exchangers. The existing temperature and condition of the production rooms is much less influenced by the baking process.

The baked product is stabilised due to the vacuum cooling process, and will lose practically no moisture (less than 4% sometimes down to 2,5%) compared to the conventional

products.

Vacuum Cooling influences the distribution of the moisture, which leads to energy saving. On freezing time for instance a 30% saving can be realised. At the same time the physical

characteristics like the crust can be improved and controlled. The baker steers the process in a detailed way, resulting in a better product with less Acrylamide and other unwanted

compounds.